Exploring the Future of Best Stamping Parts in 2025 and How to Stay Ahead in Global Sourcing

As we venture into 2025, the landscape of manufacturing is undergoing a significant transformation, and stamping parts are at the forefront of this evolution. The global market is becoming increasingly competitive, prompting businesses to refine their sourcing strategies and innovate their production processes. In particular, Chinese manufacturers are emerging as leaders in providing high-quality stamping parts that meet international standards, thanks to advancements in technology and manufacturing techniques.

This blog will explore the future of stamping parts, addressing key trends and challenges to anticipate, and offering insights on how companies can stay ahead in global sourcing. By focusing on strategic partnerships and embracing the latest industry advancements, businesses can not only enhance their operational efficiencies but also ensure they remain competitive in a rapidly changing market environment.

Join us as we delve into the opportunities and strategies that will define the future of stamping parts in the years to come.

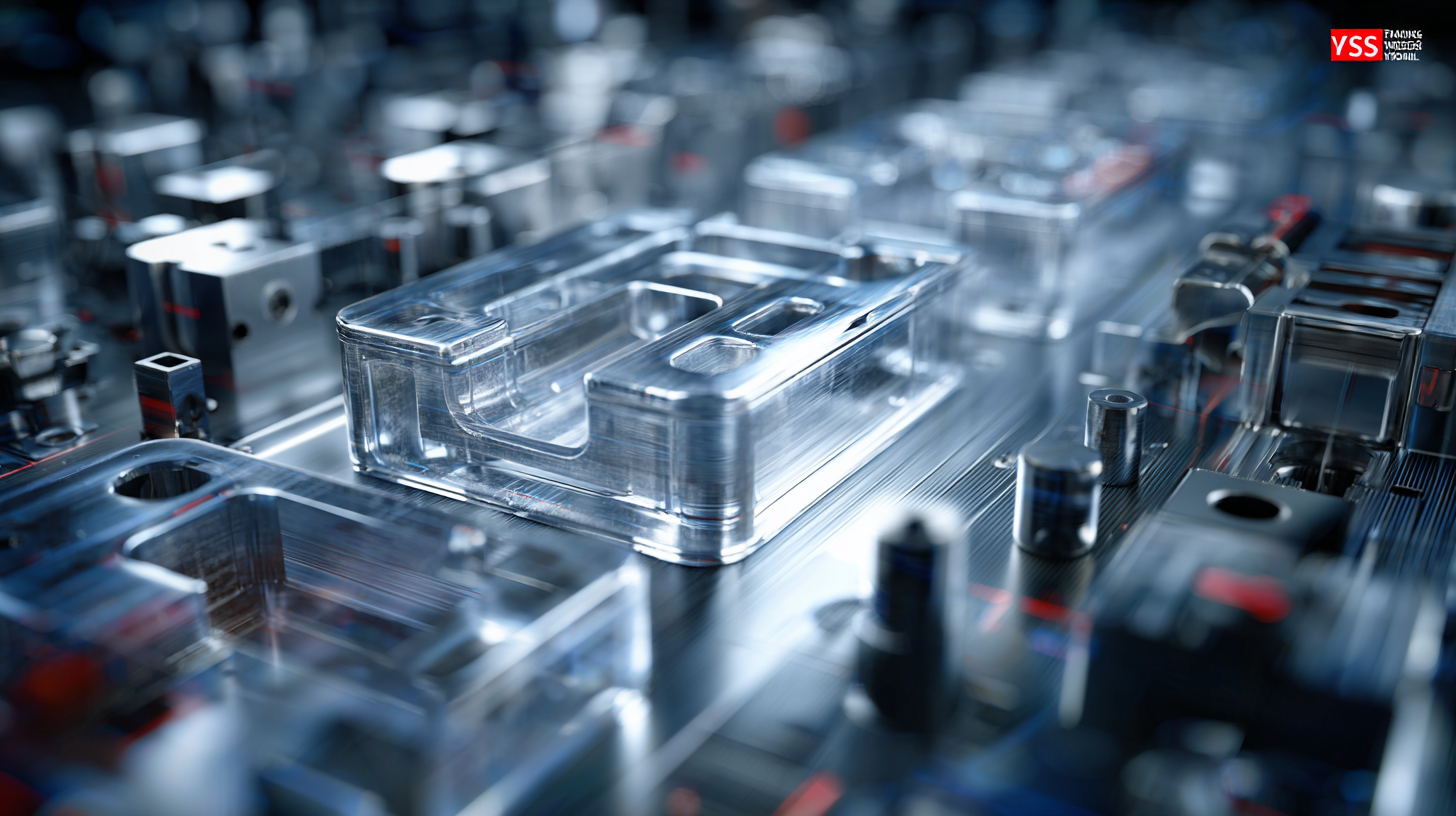

Future Trends in Stamping Parts: Innovations to Watch for in 2025

As we look toward 2025, the stamping parts industry is on the verge of significant transformations driven by technological advancements and evolving market demands. Innovations in materials, such as high-strength alloys and composite materials, are set to enhance the performance and durability of stamped components. According to a recent report by Smithers Pira, the global market for stamping parts is expected to reach $230 billion by 2025, pushing manufacturers to adopt cutting-edge technologies to stay competitive. This surge is largely attributed to increasing automation in production processes, which not only improves efficiency but also reduces operational costs.

Another critical trend shaping the future of stamping parts is the integration of smart manufacturing practices. The implementation of IoT (Internet of Things) technologies is allowing manufacturers to optimize their supply chains and enhance real-time monitoring of production lines. According to a study published by the International Journal of Advanced Manufacturing Technology, companies that leverage IoT capabilities can see productivity improvements of up to 20%. As we progress into 2025, companies focusing on these innovations will not only meet the demands for higher quality and precision but also gain a competitive edge in global sourcing.

The Role of Sustainable Practices in Global Sourcing of Stamping Parts

As global sourcing continues to evolve, the role of sustainable practices in the procurement of stamping parts is becoming increasingly critical. According to a recent report by the Global Manufacturing and Equipment Sourcing Association, organizations that prioritize sustainable sourcing practices can reduce their material costs by up to 20% and enhance their brand reputation in an increasingly eco-conscious market. With an anticipated growth rate of 4.5% in the global stamping parts industry by 2025, businesses have a unique opportunity to integrate sustainability into their sourcing strategies.

Sustainable practices in stamping parts sourcing not only focus on the environmental impact but also on the social implications of manufacturing processes. A survey by the Sustainability in Manufacturing Group revealed that 73% of consumers are more likely to purchase from companies that commit to sustainable manufacturing practices. This growing trend underscores the pressure on manufacturers to adopt eco-friendly materials and processes. By leveraging renewable resources, reducing waste, and ensuring ethical labor practices, companies can not only meet regulatory standards but also cater to the shifting preferences of consumers, thereby staying ahead in the competitive landscape of global sourcing.

Building a Reliable Supply Chain: Lessons from Chinese Manufacturing

The global landscape of manufacturing is rapidly evolving, and the lessons learned from

Chinese manufacturing are increasingly relevant for companies looking to build a reliable supply chain.

According to a report by McKinsey, nearly 70% of companies are reevaluating their supply chain strategies due to recent disruptions.

This emphasizes the importance of diversifying sources and finding dependable partners within the intricate supply networks that characterize industries such as stamping parts manufacturing.

China remains a key player in this regard, accounting for approximately 28% of the global manufacturing output as reported by the World Bank.

Companies that leverage local expertise and technology can achieve significant cost efficiencies and faster turnaround times.

By establishing long-term relationships with reputable manufacturers, firms can not only secure their supply chains

but also gain insights into innovation trends and quality control.

Investing in relationship management and technology-sharing initiatives can enhance operational resilience and product quality, ensuring a

competitive edge as we move towards 2025.

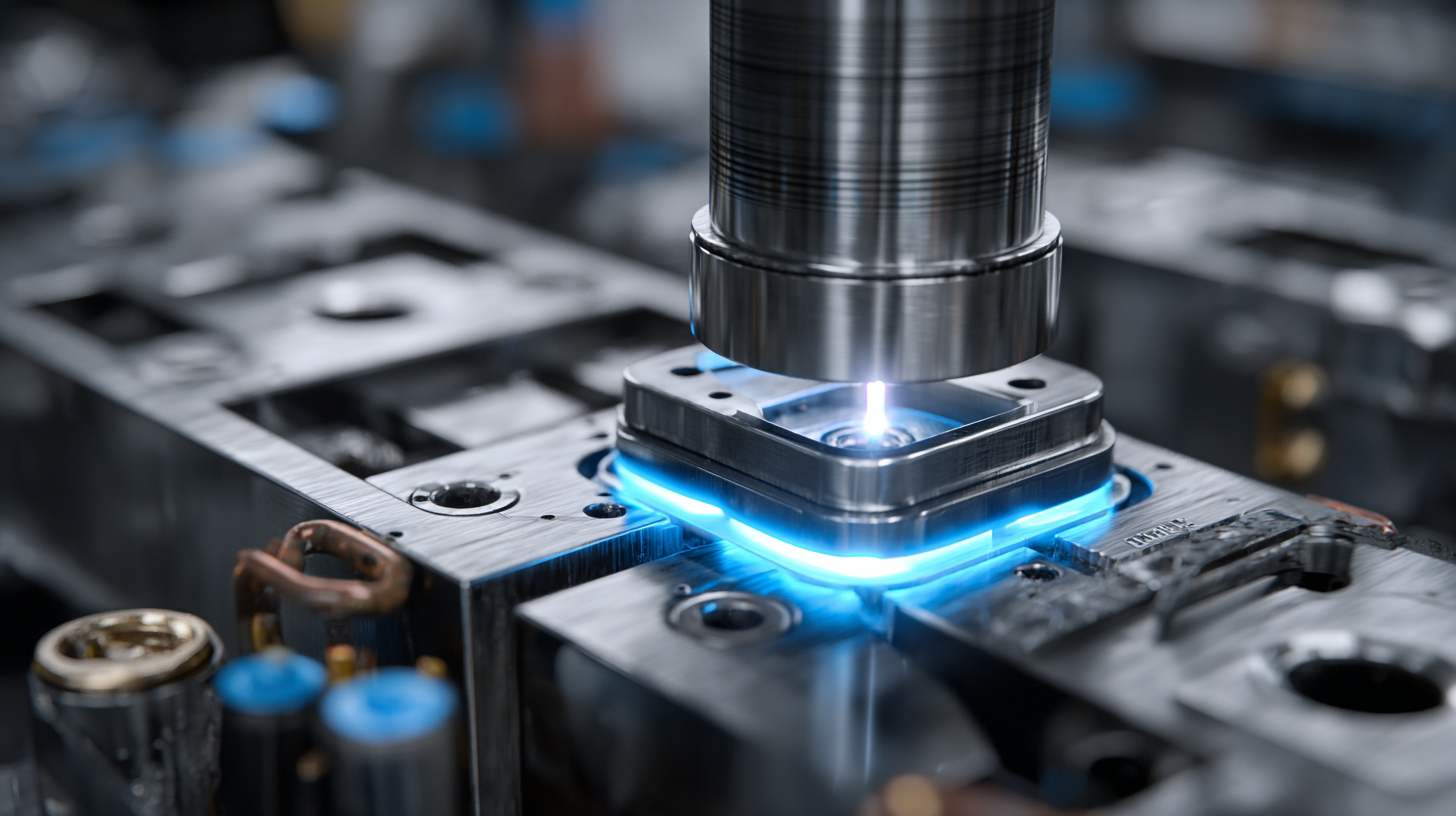

Quality Assurance in Stamping Parts: Ensuring Global Standards are Met

In the ever-evolving landscape of global manufacturing, quality assurance for stamping parts has become a pivotal focus. As industries move towards more complex and demanding applications, ensuring that stamping components meet international quality standards is essential. With 2025 on the horizon, manufacturers must adopt rigorous quality control measures that extend from material selection to the final inspection processes. This encompasses implementing advanced technologies, such as automated inspection systems and real-time monitoring, that not only enhance precision but also foster transparency throughout the production cycle.

To stay ahead in sourcing high-quality stamping parts, businesses must engage in comprehensive supplier evaluations. This involves assessing not just the technical capabilities of suppliers, but also their commitment to global quality assurance standards. Establishing strong relationships with suppliers who prioritize quality can lead to significant competitive advantages. Additionally, regular audits and feedback loops are crucial for maintaining high standards and ensuring that products comply with increasing environmental and safety regulations. By fostering this culture of quality assurance, companies can mitigate risks and ensure a sustainable supply chain in the global market.

Strategies for Staying Competitive in the Evolving Stamping Parts Market

In today’s rapidly evolving stamping parts market, staying competitive requires a proactive approach that embraces new trends and technologies. As manufacturers prepare for 2025, understanding the integration of advanced manufacturing techniques and automation will be essential. The adoption of legal technology, for instance, has revolutionized operational efficiencies across various sectors. Similarly, stamping parts manufacturers can leverage technology to streamline processes, enhance quality control, and improve customer relations.

Moreover, exploring key trends in metal stampings is crucial for maintaining a competitive edge. The industry is projected to witness robust growth, tied closely to innovations in automotive and consumer electronics. Manufacturers should focus on adopting best practices, such as sustainable sourcing and advanced materials, to remain relevant. By analyzing the competitive landscape and integrating insights from other sectors, businesses in the stamping industry can develop strategies that not only address current market demands but also anticipate future opportunities, ensuring they stay ahead in global sourcing.