Quality Stamping Parts from China Leading the Global Market with Excellence

In recent years, the global demand for high-quality stamping parts has surged significantly, driven by advancements in automotive, electronics, and aerospace industries. According to a recent market research report by Grand View Research, the global metal stamping market size is expected to reach USD 232.9 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.2%. This growth is largely attributed to the increased adoption of precision-engineered components that enhance the efficiency and performance of end products. As a manufacturing powerhouse, China has emerged as a leader in producing high-quality stamping parts, leveraging its advanced technologies and skilled workforce to meet international standards. The excellence of these parts, sourced from top-tier factories, has established a strong reputation and trust among global customers, solidifying China's position as a go-to destination for stamping solutions that drive innovation and success in various sectors.

Understanding the Importance of Quality Stamping Parts in Global Manufacturing

In today's global manufacturing landscape, the significance of quality stamping parts cannot be overstated. These components play a critical role in ensuring the reliability and efficiency of the final products, making them indispensable across various industries. High-quality stamping parts can lead to enhanced performance, reduced downtime, and increased overall productivity. Manufacturers who prioritize quality in their stamping processes are better positioned to meet customer demands and maintain a competitive edge.

Tip 1: When selecting a supplier for stamping parts, it’s essential to verify their certifications and quality control processes. A robust quality assurance system helps ensure that the parts produced meet industry standards and specifications.

Furthermore, understanding the characteristics of high-quality stamping parts is crucial. Factors such as material choice, precision in manufacturing, and surface finish all contribute to the functionality and longevity of the parts. By investing time in evaluating these aspects, manufacturers can avoid costly mistakes and rework.

Tip 2: Regularly updating the technology and machinery used in stamping processes can result in significant improvements in quality and efficiency. Staying current with advancements in manufacturing technology can help achieve better precision and consistency in the final products.

Quality Stamping Parts from China Leading the Global Market with Excellence

| Part Type | Material | Production Method | Annual Production Volume | Key Applications |

|---|---|---|---|---|

| Metal Bracket | Steel | Stamping | 500,000 units | Automotive, Electronics |

| Automotive Frame | Aluminum | Die Casting | 300,000 units | Transportation, Aerospace |

| Connector Housing | Plastic | Injection Molding | 1,000,000 units | Electronics, Appliances |

| Support Bracket | Stainless Steel | Laser Cutting | 200,000 units | Construction, Industrial |

| Cover Plate | Copper | Deep Drawing | 150,000 units | Electrical, Marine |

Key Features that Set Chinese Stamping Parts Apart from Competitors

Chinese stamping parts have increasingly gained a competitive edge globally, thanks to several key features that differentiate them from their counterparts. A recent report from MarketsandMarkets suggests that the global stamping parts market is expected to grow from $150 billion in 2021 to over $200 billion by 2026, highlighting the rising demand for high-quality components. Chinese manufacturers are leveraging advanced technologies and automation to enhance precision, resulting in lower defect rates—reportedly under 1%—which is significantly better than the global average of 2-3%.

One of the standout elements of Chinese stamping parts is their cost-effectiveness without compromising quality. According to a study by Grand View Research, manufacturing in China can reduce production costs by up to 30% compared to other regions. This efficiency allows businesses to allocate resources more effectively and invest in innovation.

Tips: When sourcing stamping parts from China, ensure to conduct thorough due diligence on potential suppliers. Look for manufacturers with certifications such as ISO 9001, which indicates a commitment to quality management. Additionally, request sample parts to assess the quality and precision before making larger orders, as this can prevent costly mistakes down the line.

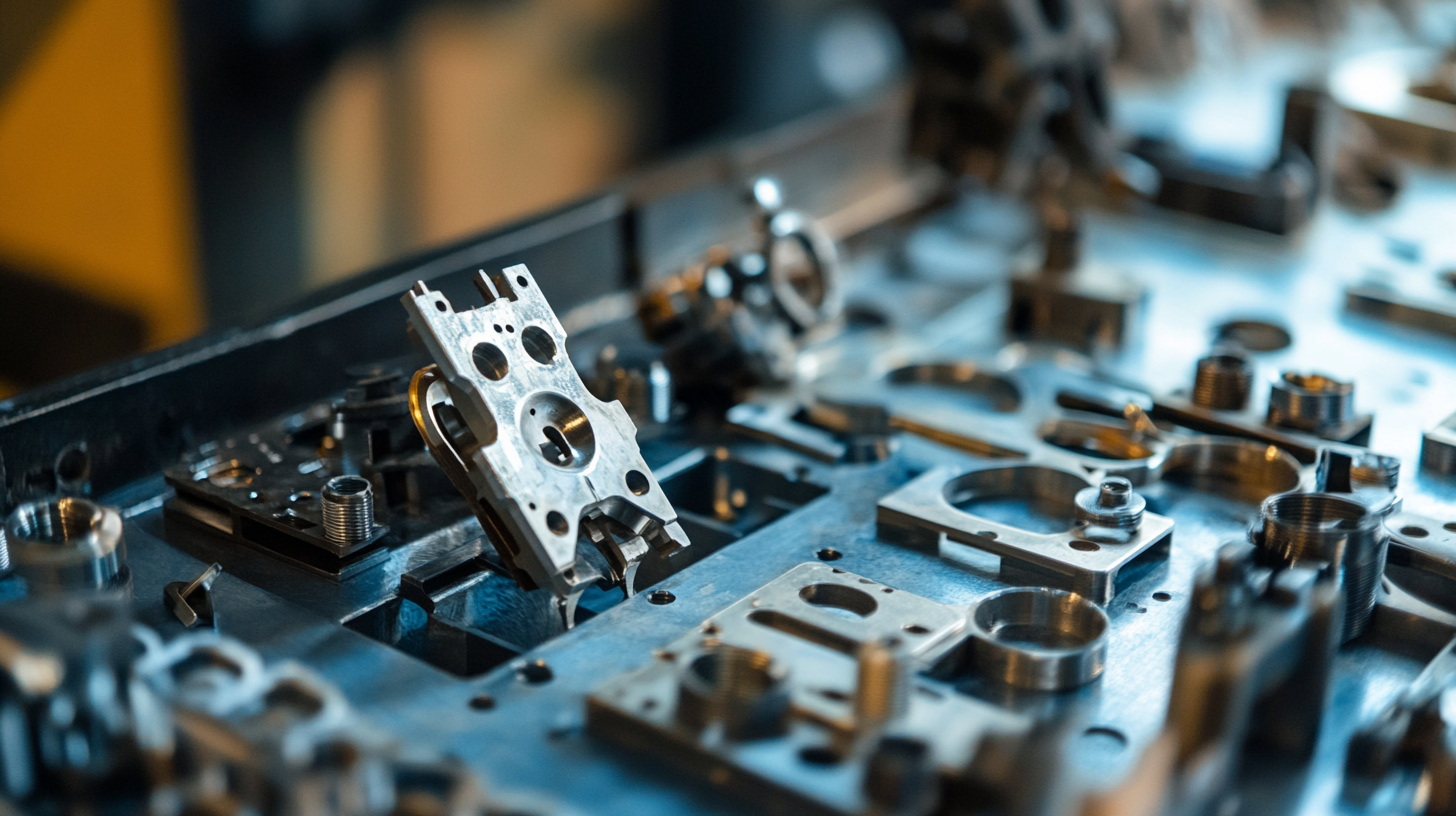

The Manufacturing Process: How China Ensures Excellence in Stamping Parts Production

The stamping parts manufacturing process in China is characterized by advanced technology and rigorous quality control, ensuring that it leads the global market. According to a recent report by Grand View Research, the global stamping market size was valued at over $170 billion in 2022, with China accounting for a substantial share due to its vast production capabilities and skilled workforce. The process involves several critical steps, including material preparation, stamping, finishing, and comprehensive testing, which collectively enhance the durability and precision of the parts produced.

Chinese manufacturers leverage state-of-the-art machinery, such as computer numerical control (CNC) equipment and automated stamping lines, to optimize productivity and consistency. A report from Mordor Intelligence indicates that the integration of automation in stamping processes has increased efficiency by 25%, significantly reducing lead times and costs. Furthermore, strict adherence to international standards, such as ISO 9001, ensures that every stamped component meets the necessary quality requirements. By investing in research and development, Chinese companies have also advanced their techniques, producing stamping parts that not only meet but often exceed global quality benchmarks.

Cost-Effectiveness: Benefits of Sourcing Stamping Parts from China

As global industries strive for cost efficiency, sourcing stamping parts from China has emerged as a strategic advantage. According to a recent report by Research and Markets, the global stamping market is expected to reach $239 billion by 2027, with China accounting for a significant share due to its competitive pricing and high production capacity. This cost-effectiveness is primarily driven by the country's vast manufacturing network and lower labor costs, which can offer savings of up to 30% compared to Western manufacturers.

Furthermore, the advanced technology and machinery utilized in Chinese stamping factories enhance precision and consistency. A study from the International Federation of Robotics revealed that China is rapidly increasing its robotics investment, contributing to improved productivity rates. This not only lowers production costs but also elevates the quality of the stamped parts. Companies leveraging this capability experience reduced lead times and lower operational costs while maintaining high standards, making China the preferred choice for stamping solutions in a globalized economy.

Cost-Effectiveness of Sourcing Stamping Parts from China

Navigating Quality Standards: Ensuring Compliance and Reliability in Stamping Parts

When it comes to manufacturing stamping parts, adhering to quality standards is crucial for ensuring compliance and reliability. The global market increasingly demands precision-engineered components that meet strict specifications. Manufacturers in China have risen to the occasion, leveraging advanced technologies and skilled labor to produce stamping parts that not only meet but often exceed international quality standards. This shift has positioned China as a leader in the global stamping parts market.

Tips for ensuring quality compliance include conducting regular audits of production processes and supplier partnerships. Establishing a quality control team that meticulously assesses raw materials and finished products can prevent issues before they arise. Additionally, it’s essential to stay updated on industry standards and regulations, as maintaining compliance can significantly enhance product reliability and customer satisfaction.

Another important aspect is fostering a strong communication channel with suppliers. This encourages transparency and helps in swiftly addressing any quality concerns. Regular training sessions for staff about the latest quality standards and compliance techniques can also reinforce a culture of excellence, ensuring that the stamping parts produced consistently meet the high expectations of the global market.