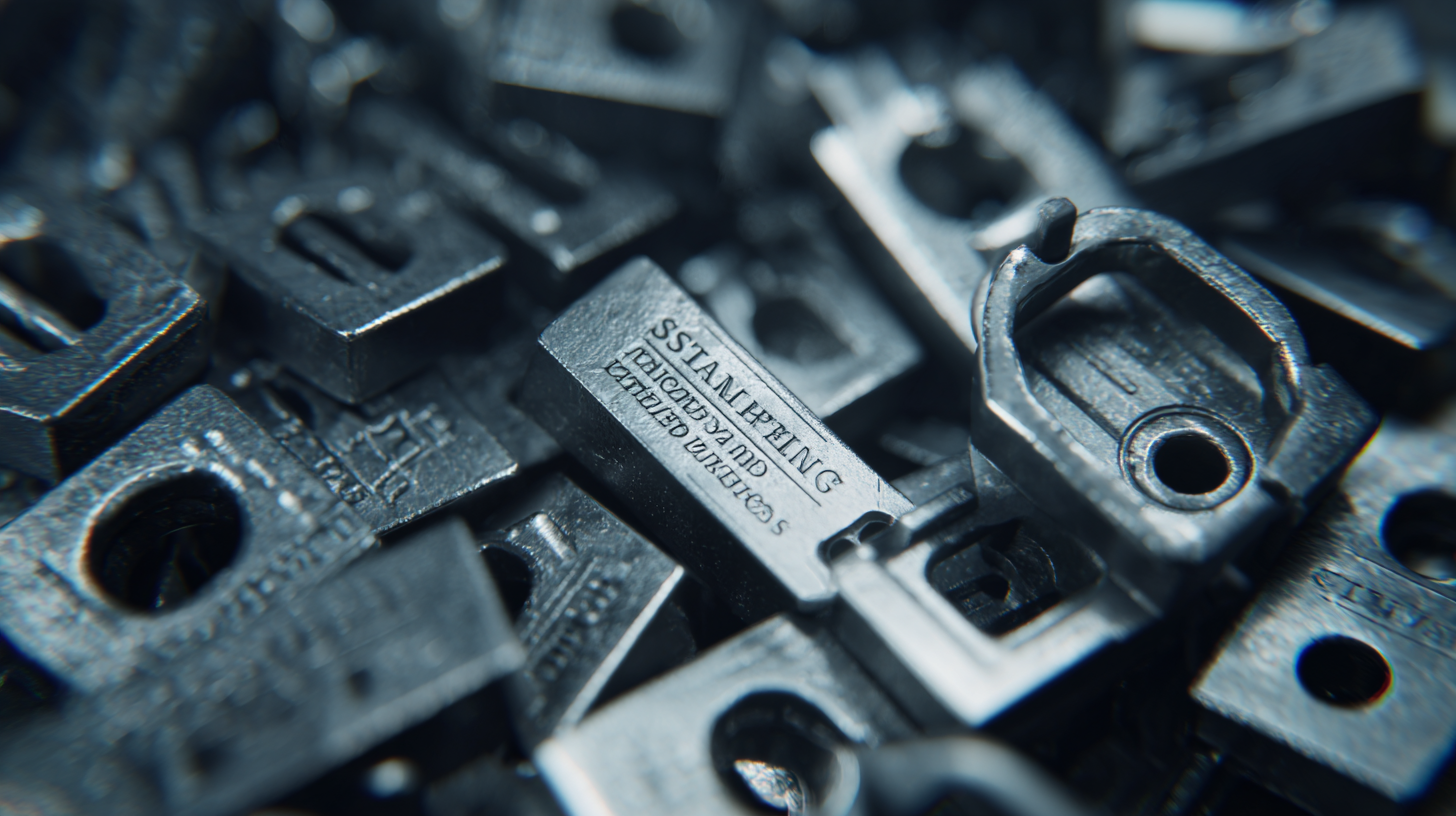

Unlocking Efficiency with the Best Stamping Parts in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the demand for efficiency and precision has never been greater. One of the key components driving this evolution is the use of high-quality stamping parts, which play a crucial role in various production processes. As manufacturers seek to optimize their operations, exploring alternatives to traditional stamping parts becomes essential. This blog will delve into innovative solutions and alternatives that not only enhance production efficiency but also ensure superior quality and cost-effectiveness.

By examining the diverse applications and advancements in stamping parts, we aim to provide insights that empower manufacturers to unlock their full potential while meeting the ever-growing demands of the industry.

The Role of Stamping Parts in Streamlining Manufacturing Processes

In today's fast-paced manufacturing landscape, stamping parts play a crucial role in streamlining production processes. These components are not just essential for creating precise shapes and designs; they also contribute significantly to efficiency and cost-effectiveness. By utilizing advanced stamping techniques, manufacturers can produce high-quality parts with minimal waste, ensuring that every resource is maximized.

In today's fast-paced manufacturing landscape, stamping parts play a crucial role in streamlining production processes. These components are not just essential for creating precise shapes and designs; they also contribute significantly to efficiency and cost-effectiveness. By utilizing advanced stamping techniques, manufacturers can produce high-quality parts with minimal waste, ensuring that every resource is maximized.

Tip: To enhance the efficiency of your stamping processes, consider integrating automation where possible. Automated stamping machines can increase production speed and reduce human error, leading to a smoother workflow.

Moreover, selecting the right materials for stamping can make a substantial difference in end-product quality. Materials that offer flexibility and durability can withstand the rigors of manufacturing while ensuring that intricate designs are accurately replicated. Adopting a strategic approach to material selection is key to optimizing manufacturing outcomes.

Tip: Regularly review and maintain your stamping equipment to prevent downtime. Scheduled maintenance can identify potential issues before they escalate, keeping production on track and ensuring consistent quality.

Key Advantages of Sourcing Stamping Parts from China

Sourcing stamping parts from China offers distinct advantages that significantly enhance manufacturing efficiency. The country has become a global leader in stamping part production, accounting for approximately 30% of the world's output, as reported by the International Organization for Standardization (ISO). This dominance is largely due to a combination of advanced manufacturing technologies and an abundant labor force, allowing for lower production costs without compromising quality.

One of the key benefits of sourcing stamping parts from China is the access to a vast network of suppliers and manufacturers, often resulting in competitive pricing and shorter lead times. According to a study by the Boston Consulting Group, companies that source components from China can reduce their production costs by as much as 20-30%. Furthermore, China's investment in automation and smart manufacturing has dramatically improved precision and efficiency, ensuring high-quality stamping parts that meet international standards. These factors collectively position China as a prime destination for businesses looking to optimize their manufacturing processes.

Unlocking Efficiency with the Best Stamping Parts in Modern Manufacturing

Innovative Technologies in Stamping for Enhanced Production Efficiency

In the realm of modern manufacturing, the pursuit of enhanced production efficiency is paramount, and innovative technologies in stamping play a critical role in achieving this goal. Stamping, a process that forms materials into specific shapes and sizes through the application of pressure, has evolved significantly. With the integration of advanced automation, manufacturers can now produce high volumes of parts with unprecedented precision and speed, reducing waste and lowering production costs.

One of the key innovations in stamping technology is the use of intelligent machinery equipped with AI and machine learning capabilities. These machines can analyze production data in real time, optimizing processes and making adjustments on-the-fly. This adaptability not only minimizes downtime but also improves product quality by ensuring that each stamp is executed perfectly. Furthermore, the introduction of high-strength materials and advanced tooling techniques allows for more intricate designs, enhancing both the functionality and aesthetic appeal of stamped components while maintaining efficiency.

Case Studies: Success Stories of Stamping Implementation in Industry

In modern manufacturing, stamping parts play a crucial role in enhancing operational efficiency, as evidenced by various case studies showcasing successful implementations. For instance, companies in industries ranging from automotive to electronics have leveraged stamping technology to streamline production processes, reduce waste, and enhance product precision. By adopting advanced stamping techniques, these organizations not only improve their manufacturing speed but also achieve significant cost savings and sustainability goals.

One notable example comes from a leading manufacturing firm that integrated innovative stamping solutions, resulting in a dramatic reduction in production time and resource consumption. This case highlights how the combination of cutting-edge technology and strategic thinking can lead to exemplary outcomes. Moreover, as environmental considerations become increasingly important, companies are exploring stamping methods that minimize emissions and promote eco-friendly practices, such as recycling scrap material. The success stories from various industries illustrate that investing in the best stamping parts not only drives efficiency but also supports a more sustainable future for manufacturing.

Future Trends in Stamping Parts Development and Manufacturing Excellence

In the evolving landscape of modern manufacturing, stamping parts are becoming increasingly vital to ensure operational excellence and efficiency. According to a report by MarketsandMarkets, the global stamping market is projected to reach $275.9 billion by 2025, driven by rising automobile production and advancements in manufacturing processes. This highlights the growing demand for high-precision stamping parts that can withstand the complexities of modern machinery. As manufacturers adopt automated stamping techniques, efficiency is expected to improve, reducing production times and waste.

Future trends indicate a shift towards smart manufacturing solutions, with the integration of Industry 4.0 technologies playing a crucial role in stamping parts development. The use of IoT devices and AI-driven analytics will not only streamline production processes but also enhance quality control, allowing for real-time monitoring and adjustments. A recent survey by McKinsey reveals that companies leveraging these technologies have seen productivity increases of up to 30%, demonstrating the potential for significant competitive advantage. As manufacturers prioritize innovation in stamping technologies, the efficiency gains could revolutionize production methods, setting new standards in manufacturing excellence.