2026 Top Orthopedic Implant Innovations and Trends?

The field of orthopedic implants is rapidly evolving. Innovations in technology drive improvement in patient outcomes. Dr. John Matthews, an orthopedic implant expert, states, “The future lies in personalized solutions for effective mobility.” This highlights a key trend in tailoring implants to individual needs.

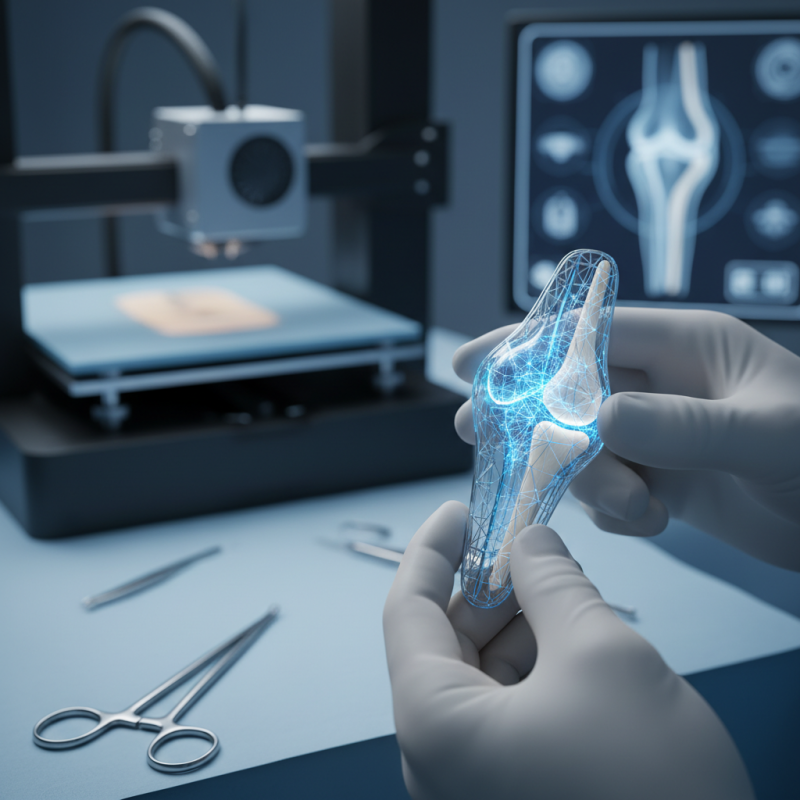

In recent years, the focus has shifted towards biocompatible materials and 3D printing technologies. These advancements enable surgeons to create customized implants for complex cases. However, challenges remain. Not all materials perform optimally in every patient. Long-term data on these innovations is still being collected.

The trend towards minimally invasive procedures also shapes the orthopedic implant landscape. While promising, these techniques still face skepticism among some practitioners. Balancing innovation with proven methods requires constant reflection and adaptation. The future of orthopedic implants looks bright, yet the journey is fraught with learning opportunities.

Emerging Technologies in Orthopedic Implants for 2026

Emerging technologies in orthopedic implants for 2026 are shaping the future of medical care. One significant trend is the use of 3D printing. This technology allows for custom implants that precisely match a patient's anatomy, offering enhanced fit and comfort. However, the process can be slow and resource-intensive. Quality control remains a concern, as not all printed materials meet the required safety standards.

Another exciting development involves biocompatible materials. Smart materials can adapt to the body's environment. For instance, some materials can release drugs or stimulate tissue growth. While this holds great promise, the long-term effects on the human body are still unknown. More research is needed to ensure their safety and effectiveness.

Robotics and AI are also playing a role in surgery. These technologies assist surgeons by providing advanced imaging and precision tools, improving outcomes and reducing recovery times. Yet, reliance on machines can lead to ethical questions. The balance between human skill and technology needs careful consideration in the medical field.

Innovations in Biodegradable Materials for Orthopedic Devices

The future of orthopedic devices is bright, especially with innovations in biodegradable materials. These new materials offer exciting possibilities. They not only reduce long-term complications but also enhance patient comfort. Imagine a device that naturally dissolves over time, eliminating the need for additional surgeries.

Tips: Patients should ask about new materials during consultations. Understanding how biodegradable devices work is crucial for informed decisions.

Biodegradable materials can significantly decrease infection rates. Traditional implants can sometimes cause adverse reactions. It's a challenge for manufacturers to ensure these new materials are safe and effective. Not all biodegradable options are created equal, and that’s worth discussing with healthcare professionals.

Tips: Research and compare different biodegradable options. Awareness of ongoing advancements leads to better choices for your health.

| Innovation | Description | Material Used | Potential Benefits | Market Adoption Status |

|---|---|---|---|---|

| 3D Printed Implants | Custom implants designed using advanced 3D printing technology. | Titanium alloys, PEEK | Improved fit, reduced surgery time | Increasingly adopted in surgeries |

| Biodegradable Scaffolds | Scaffolds that degrade over time to promote natural tissue growth. | Polycaprolactone, PLA | Eliminates second surgery for removal, enhances healing | In clinical trials |

| Smart Implants | Implants that monitor patient movements and healing through sensors. | Biocompatible metals and polymers | Real-time health monitoring, improved patient outcomes | Limited adoption, mainly in research |

| Self-Integrating Coatings | Coatings that promote osseointegration with the bone. | Hydroxyapatite, bioactive glass | Faster healing, reduced implant failures | Gradual market uptake |

| Antimicrobial Implant Materials | Materials infused with antimicrobial properties to prevent infections. | Silver-infused polymers, antibacterial coatings | Reduced infection rates, enhanced safety | In the process of gaining traction |

Trends in Personalized Orthopedic Implant Design and Customization

The field of orthopedic implants is witnessing significant changes. Personalized implant design is at the forefront. This approach tailors each implant to match the specific needs of a patient. With advanced imaging technology, surgeons can create models that reflect a patient's unique anatomy. This level of customization aims to improve comfort and functionality.

Tips: When considering personalized implants, communicate openly with your surgeon. Ask about the latest technologies available. Understand the process, even the challenges it may involve.

Customization isn’t without its obstacles. Not all patients may be eligible for personalized designs due to various factors. However, even standard implants are evolving. They increasingly feature customizable options, such as adjustable features for better fit. Developments in 3D printing also promise new possibilities but come with their own complexities. Understanding these can help patients make informed decisions.

2026 Trends in Personalized Orthopedic Implant Design and Customization

Advancements in Robotics and AI for Orthopedic Surgery Applications

The integration of robotics and artificial intelligence in orthopedic surgery is transforming patient care. Surgeons can now utilize advanced robots for precision. These technologies help reduce the risk of complications and improve recovery times. The robotic systems enhance the accuracy of joint replacements. They allow for less invasive procedures, leading to smaller incisions.

AI algorithms assist in preoperative planning. They analyze patient data to predict outcomes and customize surgical strategies. However, reliance on these technologies can raise concerns. Surgeons must still exercise their judgment. There is always the risk of technical malfunctions or incorrect AI assessments. This balance between human skill and machine efficiency remains critical for patient safety.

Training for surgeons must evolve alongside these technologies. Continual education in robotics and AI is essential. Yet, there may be gaps in learning. Not every surgeon has access to advanced training programs. The challenge lies in ensuring that all orthopedic specialists can harness these innovations effectively. As we move toward 2026, addressing these issues will be paramount in enhancing orthopedic care.

Impact of 3D Printing on Future Orthopedic Implant Production

The impact of 3D printing on orthopedic implant production is profound. This technology allows for the creation of highly customized implants tailored to individual patient anatomies. According to a recent industry report, 3D printing can reduce production time by up to 50%. This efficiency can significantly influence surgical outcomes and patient recovery.

However, challenges remain. The quality and reliability of 3D-printed materials must be carefully monitored. Some studies suggest that the mechanical properties of these materials may not always match those of traditional implants. This raises concerns about their long-term performance. Furthermore, the regulatory landscape for 3D-printed implants is still developing. Ensuring patient safety is paramount, and rigorous testing is essential.

Despite these hurdles, the potential for innovation is remarkable. 3D printing enables complex designs that were previously impossible to fabricate. For example, implants with intricate internal structures can promote bone growth and integration. As the technology matures, we may see a shift towards more personalized solutions in orthopedic care. This trend could change how orthopedic surgeons approach treatment planning altogether.