Maximizing Efficiency in Food Packaging: The Benefits of Industrial Aluminum Foil Rolls

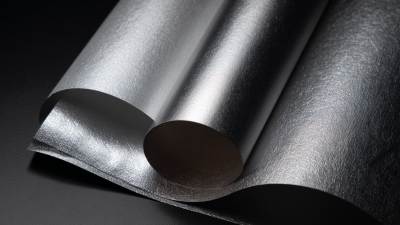

The food packaging industry is undergoing a significant transformation, with efficiency and sustainability at the forefront of innovation. Among the various materials revolutionizing this sector, industrial aluminum foil rolls stand out for their remarkable benefits. According to a report by MarketsandMarkets, the global aluminum foil market is projected to reach USD 39.4 billion by 2026, driven by the increasing demand for lightweight and sustainable packaging solutions. Industrial aluminum foil rolls are not only lightweight and versatile but also offer superior barrier protection against moisture, light, and air, prolonging the shelf-life of food products. Additionally, their recyclability aligns with the growing emphasis on environmentally-friendly practices within the industry, as highlighted in a recent study by the European Aluminum Association, which states that aluminum foil can be recycled indefinitely without degradation of its properties. This paper explores the multifaceted advantages of industrial aluminum foil rolls in maximizing efficiency in food packaging while contributing to sustainable practices.

The Role of Industrial Aluminum Foil Rolls in Food Preservation

Industrial aluminum foil rolls play a crucial role in food preservation, offering a reliable solution for maintaining the freshness, taste, and quality of various food products. Their excellent barrier properties protect against moisture, light, and air, which are primary factors in spoilage. By wrapping food in aluminum foil, manufacturers can significantly extend shelf life, minimizing waste and ensuring that products reach consumers in optimal condition.

- Layer Wisely: When wrapping food items, consider using multiple layers of aluminum foil for better protection against external elements.

- Temperature Matters: Utilize aluminum foil rolls in both hot and cold applications. They can withstand high temperatures, making them suitable for baking and grilling while also being effective for storing leftovers in the refrigerator.

Furthermore, the versatility of industrial aluminum foil rolls makes them an invaluable asset in the food industry. They can be tailored to specific needs, including custom sizes, thickness, and coatings, ensuring that businesses can optimize their packaging processes. By investing in high-quality aluminum foil rolls, manufacturers can enhance their operations and deliver superior products to their customers.

Enhancing Food Safety Through Efficient Packaging Solutions

Efficient food packaging is crucial in today's fast-paced food industry, and industrial aluminum foil rolls play a significant role in enhancing food safety. These foil rolls provide a barrier against moisture, air, and light, which can lead to spoilage and contamination. By preserving the integrity of food, aluminum foil ensures that products remain fresh and safe for consumption over longer periods. This is especially important for perishable items, where the risk of bacterial growth is high.

Moreover, the versatility of aluminum foil allows for various packaging methods, including wrapping, lining, and coating. This adaptability not only optimizes the packaging process but also helps reduce waste. By utilizing aluminum foil efficiently, manufacturers can minimize leftovers and ensure that food is securely packaged without unnecessary excess material. As a result, food recalls due to packaging failures can be significantly reduced, enhancing overall consumer safety and trust in the products they purchase. In an industry where food safety is paramount, maximizing the benefits of industrial aluminum foil rolls is an essential strategy for food producers.

Cost-Effectiveness: Savings with Industrial Aluminum Foil

In the competitive landscape of food packaging, industrial aluminum foil rolls stand out for their cost-effectiveness and efficiency. With the rising costs of materials and the increasing demand for sustainable options, businesses are rapidly shifting towards aluminum foil packaging. These rolls not only provide excellent protection against moisture and air, ensuring food safety, but also offer significant savings through reduced waste and lower transportation costs due to their lightweight nature.

Tips for maximizing the benefits of aluminum foil rolls include investing in high-quality suppliers to ensure consistency in product performance. Additionally, companies should consider implementing more automated packing solutions to enhance efficiency further. By optimizing storage space and minimizing handling, businesses can significantly reduce operational costs.

Moreover, staying informed about advancements in packaging technology can also lead to cost savings. For example, integrating a heat recovery system in plants can enhance energy efficiency, directly impacting the bottom line. As industries strive for sustainability, adopting aluminum foil packaging becomes not only a practical choice but also a pathway to long-term financial benefits.

Sustainability Benefits of Using Aluminum Foil in Food Packaging

Aluminum foil has increasingly gained recognition in the food packaging industry, not only for its efficiency but also for its sustainability benefits. According to a recent report by the Aluminum Association, aluminum foil is 100% recyclable and can be recycled endlessly without losing its quality. This attribute significantly reduces the environmental impact associated with single-use packaging materials. In fact, the recycling of aluminum saves approximately 95% of the energy required to produce new foil from raw materials, making it a greener choice for food packaging.

Aluminum foil has increasingly gained recognition in the food packaging industry, not only for its efficiency but also for its sustainability benefits. According to a recent report by the Aluminum Association, aluminum foil is 100% recyclable and can be recycled endlessly without losing its quality. This attribute significantly reduces the environmental impact associated with single-use packaging materials. In fact, the recycling of aluminum saves approximately 95% of the energy required to produce new foil from raw materials, making it a greener choice for food packaging.

Moreover, industrial aluminum foil rolls contribute to waste reduction in various food packaging applications. The European Aluminum Foil Association (EAFA) states that aluminum foil can extend the shelf life of products by providing a barrier against light, air, and moisture. This prolongation not only minimizes food spoilage but also reduces the overall volume of food waste, supporting sustainable consumption practices. As consumers become more eco-conscious, the demand for packaging solutions that prioritize both efficiency and sustainability is likely to grow, positioning aluminum foil as a front-runner in environmentally responsible food packaging options.

Innovative Applications of Aluminum Foil in the Food Industry

Aluminum foil has become an essential material in the food industry, transforming packaging solutions with its unique properties. Its ability to create a barrier against light, moisture, and oxygen makes it ideal for preserving the freshness and flavor of a wide range of food products. From wraps and bags to trays and containers, aluminum foil can be tailored for innovative applications that cater to consumer needs while enhancing shelf life.

Tips for food manufacturers include investing in high-quality aluminum foil that is specifically designed for food applications. This not only ensures safety but also optimizes performance in various conditions. Additionally, consider customizing packaging sizes to minimize waste and improve convenience for customers. Utilizing recyclable foil options can further appeal to environmentally conscious consumers, supporting a sustainable approach in food packaging.

The versatility of aluminum foil extends beyond simple wrapping; it can facilitate cooking and reheating by allowing food to retain moisture and heat evenly. Techniques such as pouch cooking or steam cooking in foil are gaining popularity, providing efficient and healthy meal solutions. Embracing these innovative applications can significantly boost efficiency in food packaging while meeting the evolving demands of the market.

Related Posts

-

The Benefits of Using Aluminium Foil Paper for Safe and Sustainable Food Packaging

-

Innovative Uses of Aluminium Foil Paper for Food Packaging You Never Knew Existed

-

Unlocking the Benefits of Aluminum Foil: Your Guide to Choosing the Right Supplier

-

Exploring Silver Foil Paper Trends and Market Dynamics at the 138th Canton Fair 2025 in China

-

Exploring Market Trends for Wrapping Foil at the 138th Canton Fair 2025 in China

-

The Environmental Impact of Food Paper Products on Sustainable Packaging Solutions